For the last few weeks i have been making and welding into place the required repairs on this 280CE,but most of the work has been concentrated on the Right side front floor and sill structure.

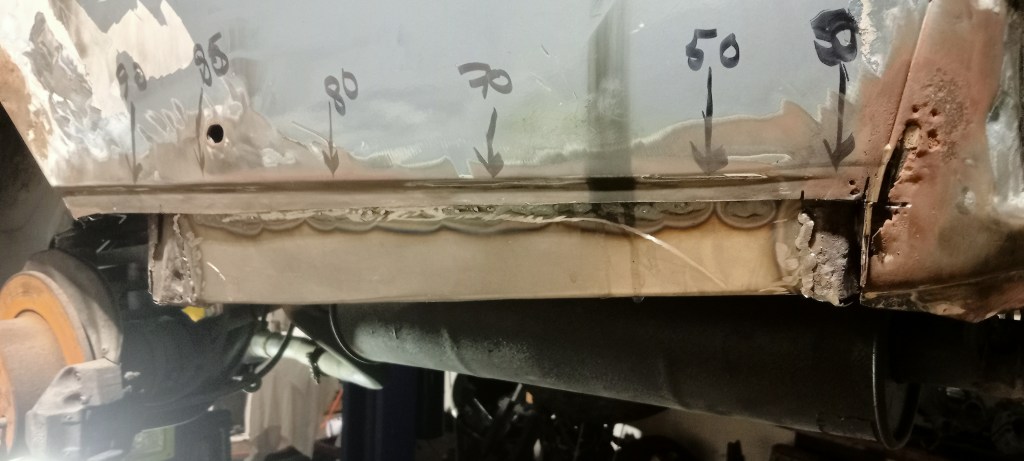

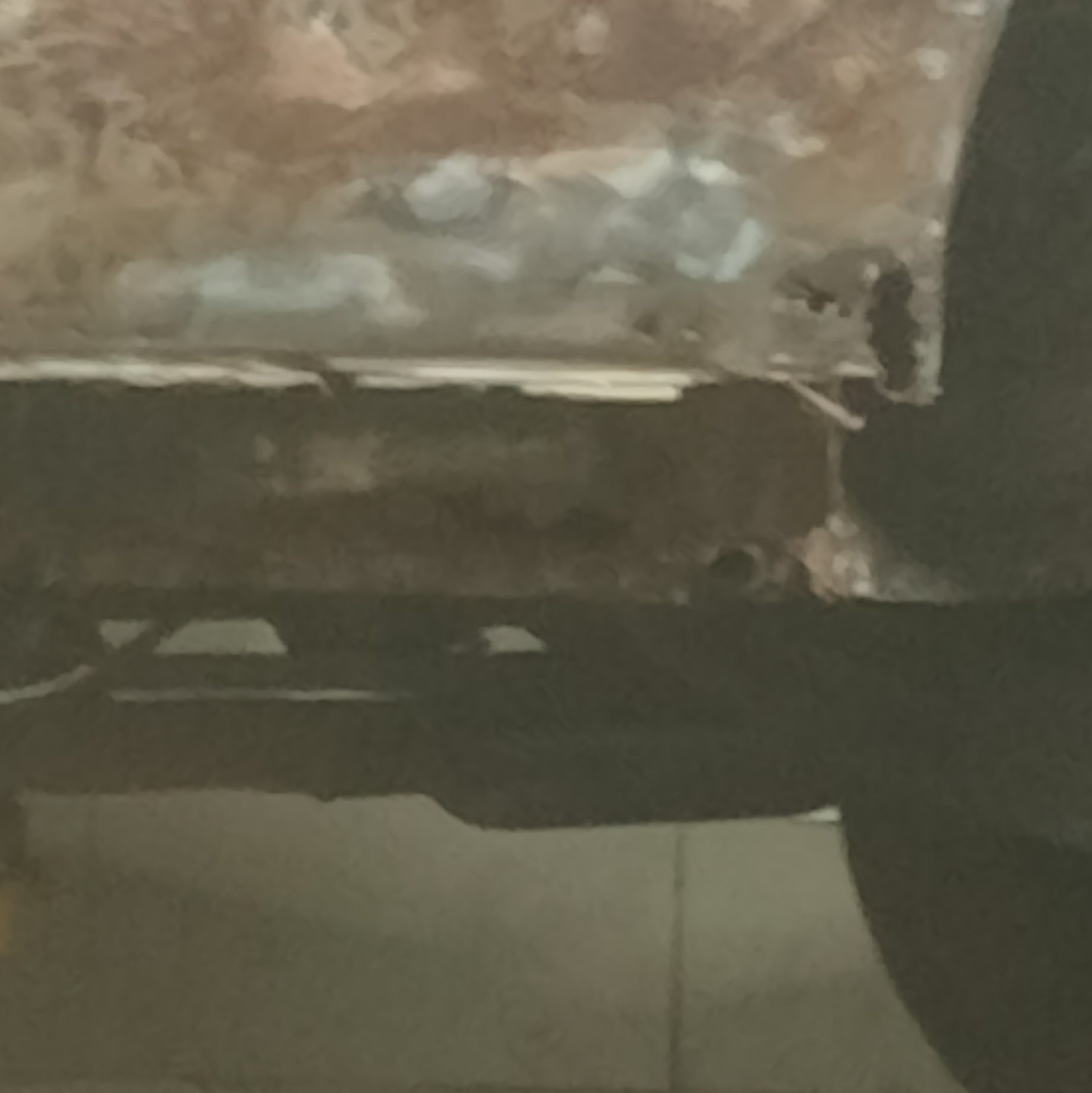

As more rust has been uncovered ,the rockers have to be fixed before any more rust removal can be addressed,once again to prevent the car collapsing.

Inside it is the usual story,lots of foreign ‘stuff’ used to hold things together .Fortunately there isn’t much rust in the rest of the panel.

I found one reason why the car didn’t run very well . the two Lines in the pic,the white and Black ones,are vacuum lines for the central locking. the engine was sucking a lot of air at idle throwing the engine tune right out. An electric central locking had been fitted.

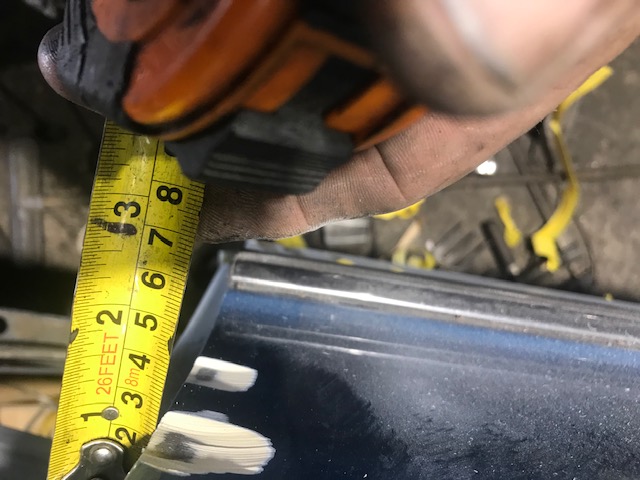

The Seat mount was held in place with a pair of roofing screws and two pieces of rubber which had been glued to the floor. One of the screws had missed and most of the floor and inner sill section was gone completely.

Most of the floor here was rusted away and once all the various substances stuck on it to prevent feet falling through were removed it became clear where the rust began and could be trimmed up.

The rust in the low middle of the picture runs right across the car ,so the only option is to remove the diff so it can be reached easily.

Because there is insufficient places to support the car while the back end is removed,I have it sitting up on blocks of wood.

22/11/2021.

More rust uncovered….

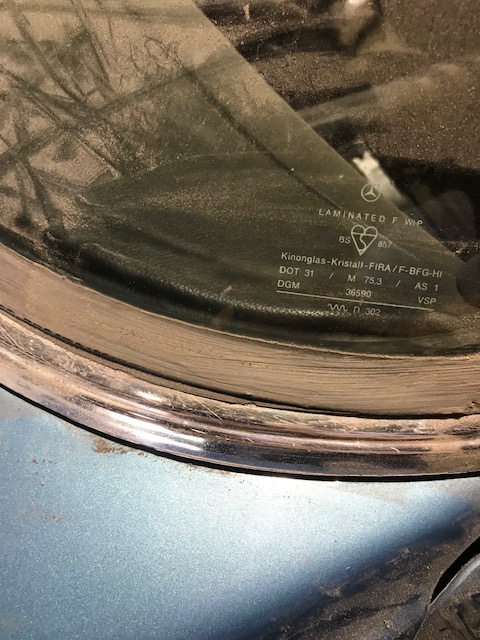

Further to this ,the boot seal was removed and the lower edge was rusted completely under some poorly applied filler.

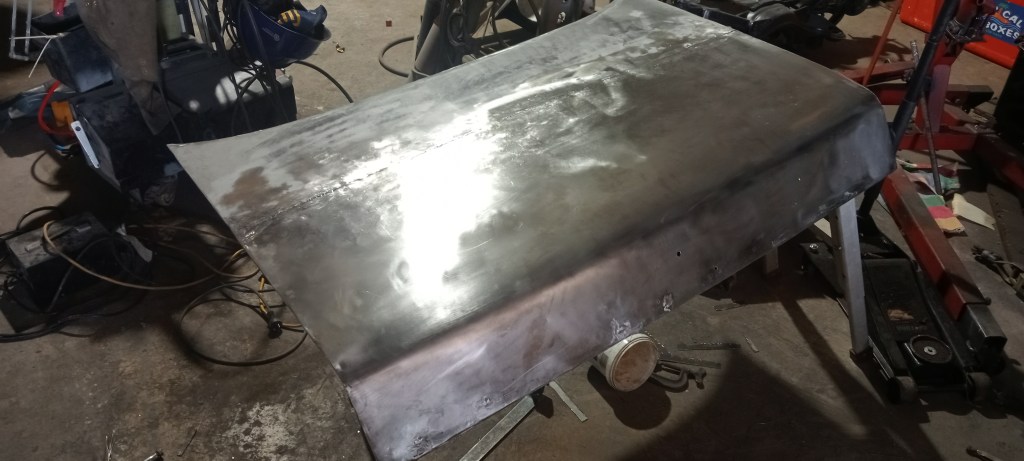

The spot welds holding the panel on are drilled out then the skin is removed. The Lower section (on the right of the picture was rusted and covered in filler to disguise the damage. The holwe is for the forward bumper bolt.

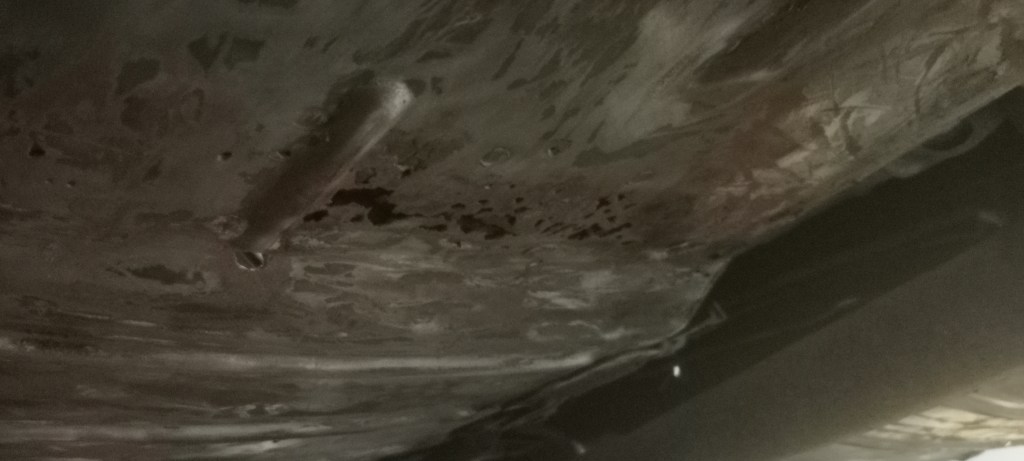

Here ,besides lot of rust holes and attempts to disguise it with filler is a large dent ,the dark area. The filler is very thick here.

This is mostly Filler