All Cars coming to me have often been under used and as a result suffer from the effects of today’s fuel which not only attacks the old style fuel hose but also attracts moisture ,which in turn destroys the inside of the tank. Following is what it takes to get a tank back into service. This is a tank is a W108 item from a W112 300SE which ,because new ones are too expensive and good used ones are rare now ,will be cleaned .It has been sitting for over 20 years with the toxic remains of fuel in it . The basic tank is almost rust free, so the first step is too…

…Cut an access hole above the internal swirl pot .

Looking inside ,a pile of the solidified remnants of the fuel. The smell alone is probably dangerous so every effort is made to avoid contacting this stuff.

inside the Swirl pot ,it’s even worse where the stuff had collected .

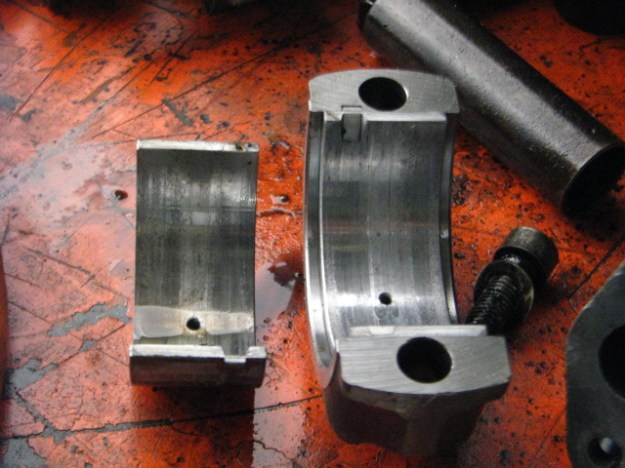

The Swirl pot is held in place by three metal tabs bent over .These are carefully bent up to release the swirl pot so it can be removed .

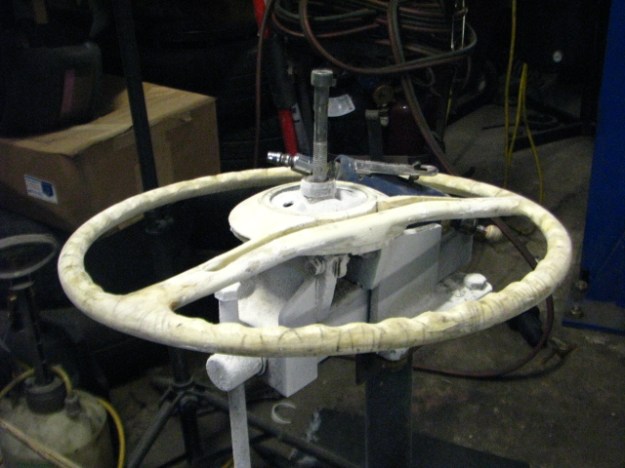

The swirl pots bottom looks like this. The piece on the lower part in picture is the venturi where fuel from the main cavity of the tank enters and is drawn in by hot fuel coming back from the engine.

The swirl pot will be thoroughly cleaned in the wet blaster . Fuel is fed to the engine through a filter mounted in the center of the swirl pot . A large pipe is routed to the pump outside the tank. A smaller line feeds hot fuel from the engine to the swirl pot ,making it swirl around the outside diameter of the inside surface of the pot,eliminating bubbles of fuel gas and cooling the fuel.

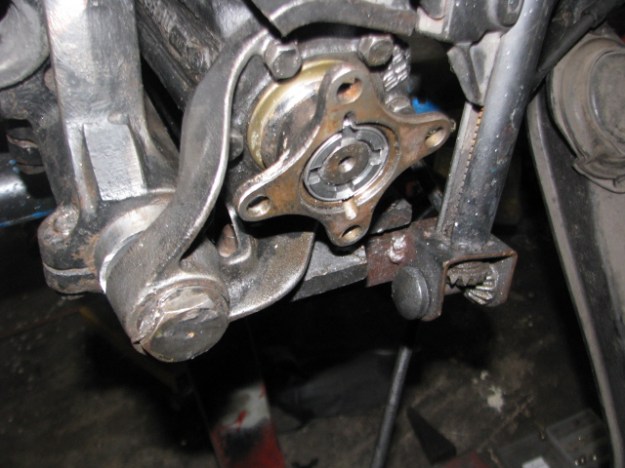

The original fuel lines on the tanks were of course rotten and it’s always a part of recommissioning these cars to replace these hoses.

This tank had the usual blocked pipes ,a common problem ,even on cars which are driven regularly .To prevent this, a dose of 1 liter of ATF (Dex III) per 100 liters of fuel keeps these pipes in good condition and on MFi equipped engines,keeps the pumps and injectors in good condition.

Here,I am poking a piece of TiG welding wire into the feed pipe to clear the congealed fuel residue out .

Sticking a piece of wire into the pipes to clear them will Not move the deposits So here I am using a Small Drill to twist the wire while feeding it into the pipe. This breaks the deposits up clearing the pipe which is then cleaned out with a wire brush .

This is the Filter hole in the bottom of the tank showing just some of the deposits forced out of the main feed tube by the drill driven wire. i use a bit of 50/50 penetrating fluid (50% brake fluid,50% acetone) to lube the wire and assist it to get the stuff to move.

Next move is to scrub the inside of the tank to remove all of the deposits stuck to the inside of the tank ,replace the cleaned Swirl pot and weld the hole back up. The tanks are then sealed with a tank sealer to prevent rust and protect the tank against today’s fuel .

To be continued…..